Services

Field Inspection Services

We’ll bring the shop to you.

Need us to come out to inspect your drilling tools? We can bring our JA Oilfield Services trailer to your drill site and provide a wide variety of inspection and repair services to get you back to work.

Pipe Inspection

BHA Inspection

Hardbanding

Pipe Buildup

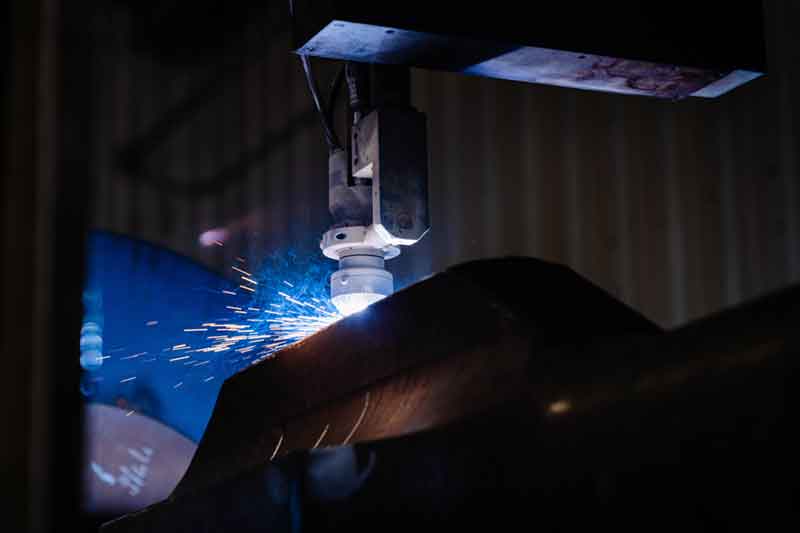

Hardbanding Services

Protecting your drilling tools from abrasive wear is crucial to avoiding delays and loss of production due to damaged down-hole components.

Hardbanding is the process of depositing a protective layer of super hard metal onto drill pipe tool joints, collars and heavy weight pipe in order to protect both the casing and drill string components from wear associated with drilling practices.

Hardbanding processes:

Wire

PTA Powder

Mobile PTA Hardbanding

Need hardbanding completed onsite? Our patented Mobile PTA hardbanding unit can come to you. We can repair and apply hardbanding to your downhole tools and keep your operation running efficiently.

Hardbanding onsite

Can be deployed offshore

Clean Drift and Tally

Cleaning Process

Thoroughly eliminate excess grease and grime from the mill manually, followed by the meticulous cleaning of connection threads using high-powered diesel units equipped with burners. Leveraging our expertise in pipes and casings, we will inspect thread compatibility, ensuring that each accessory is the appropriate fit and ready for casing deployment.

Drifting Procedure

Employing a diverse array of API drifts, the drifting process guarantees that every joint is devoid of obstructions and complies with API drift tolerances.

Tallying Method

We employ standard tallying techniques and our commitment is to furnish an impeccably accurate tally sheet, available in hard copy, digital format, or both.